Comparison: CuCr1Zr alloy and Powerode®

|

- |

- |

- |

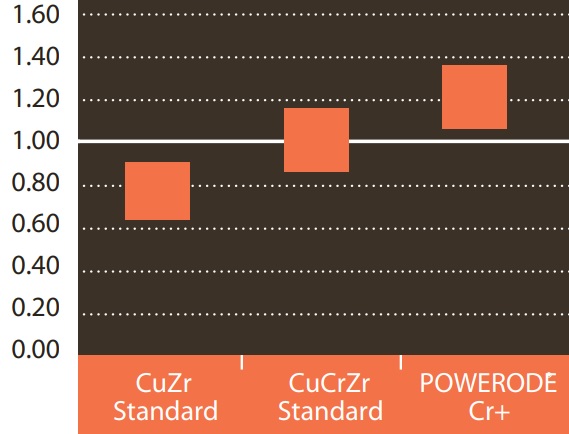

CuCr1Zr Powerode Cr+, CuCr1Zr standard |

|

Comparison: CuCr1Zr alloy and Powerode®

Lebronze alloys and Laska pay great attention to the process of continuous improvement of their offer. Thanks to close cooperation with automotive manufacturers and implemented research and development programmes in Le bronze alloys, a dedicated and patented production process for Powerode® electrodes was developed.

Very high quality and very high purity, Powerode® alloys offer greater advantages than electrodes from standard CuCr1Zr alloys.

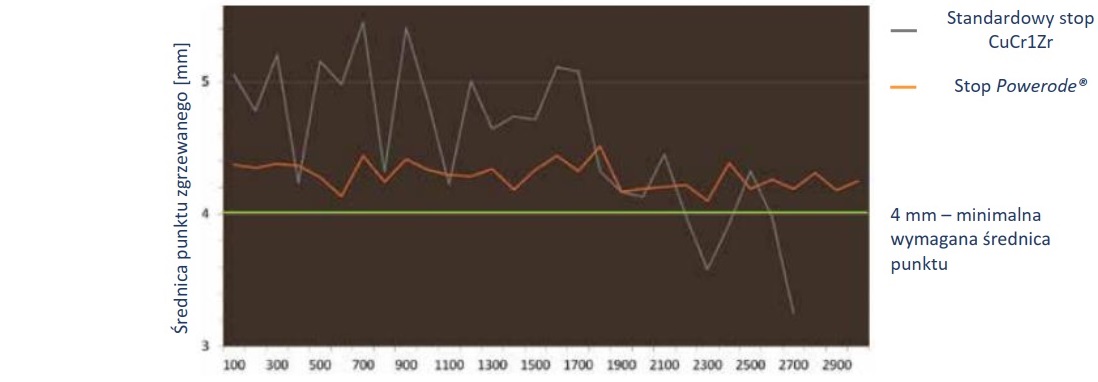

Increasing the number of welds before and between milling

The Powerode® self-protecting layer prevents damage to the electrode surface, which reduces the amount of material to be removed during the milling process.

The number of welding points is measured for each type of electrode cap, we take CuCr1Zr as a standard.

The graph shows that Powerode® electrodes have more welding points than standard electrodes.

Tests conditions:

I constant: 9,600 A

Steel: XSG 0,7mm / 0,7mm galvanized 10 µm

Protocol: welding point is accepted if dia >4 mm. No intermediary dressing

All tests have been performed by IMATB laboratory of UBS university (France).

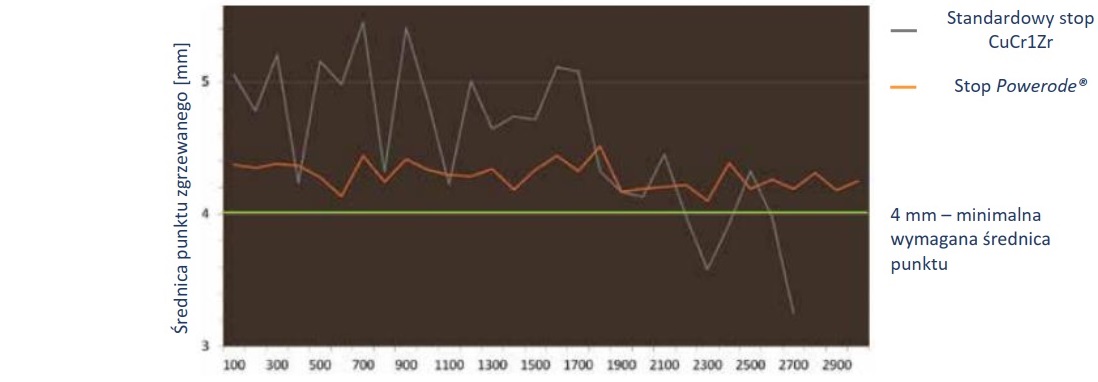

Stable, repeatable and enhanced results

High stability and increased number of points between milling for Powerode® alloy, compared to standard CuCr1Zr electrodes, even after exceeding 2,000 welded points.

For more information on how to compare Powerode® alloy with CuCrZr standard, please see the catalogue for download.

Download data sheet

|

|

|

Standard welding electrode caps ISO 5821 |

13-20 mm |

18-22 mm |

CuCr1Zr Powerode Cr+ |

|

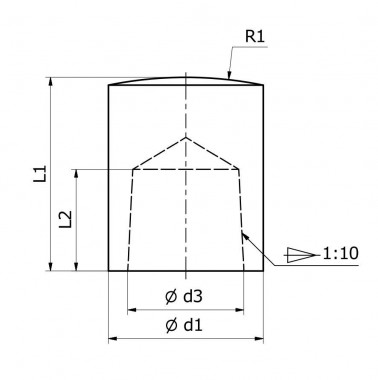

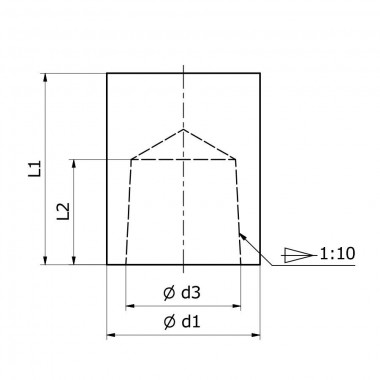

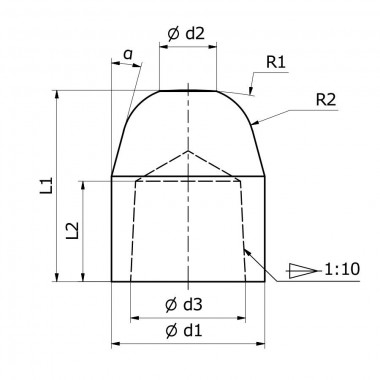

Form A

Welding electrode caps ISO 5821/DIN 44750

Material:

CuCr1Zr Powerode Cr+

Powerode+® - material of very high quality and very high purity. The technology of the production process allows for an increase in service life up to 20% and provides better electrical conductivity compared to standard electrodes.

Pressure forces:

2,5 - 6,3 [kN]

| d1 h11 |

d3 |

L1 |

L2 |

R1 |

| 13 |

10 |

18 |

8 |

32 |

| 16 |

12 |

20 |

10,5 |

40 |

| 20 |

15 |

22 |

11,5 |

50 |

Download data sheet

|

|

|

Standard welding electrode caps ISO 5821 |

13-20 mm |

18-22 mm |

CuCr1Zr Powerode Cr+ |

|

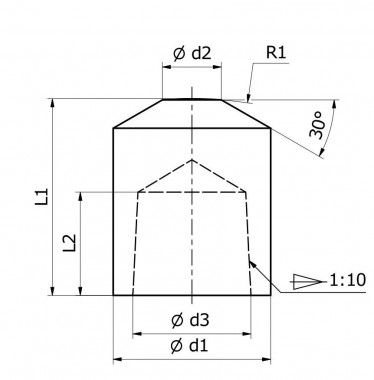

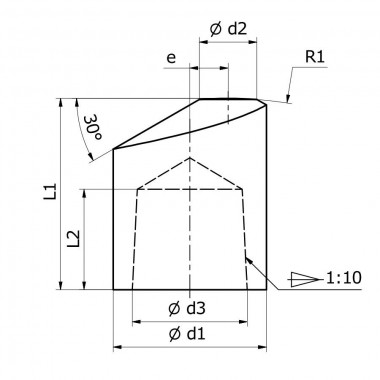

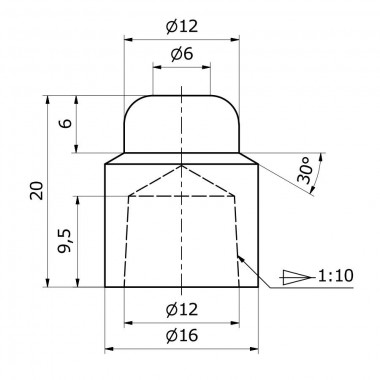

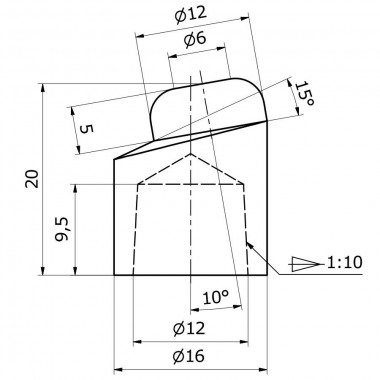

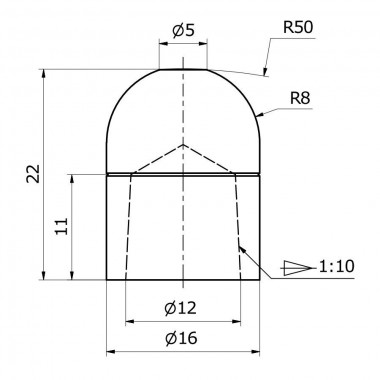

Form B

Welding electrode caps ISO 5821/DIN 44750

Material:

CuCr1Zr Powerode Cr+

Powerode+® - material of very high quality and very high purity. The technology of the production process allows for an increase in service life up to 20% and provides better electrical conductivity compared to standard electrodes.

Pressure forces:

2,5 - 6,3 [kN]

| d1 h11 |

d2 |

d3 |

L1 |

L2 +0,5 |

R1 |

| 13 |

5 |

10 |

18 |

8 |

32 |

| 16 |

6 |

12 |

20 |

10,5 |

40 |

| 20 |

8 |

15 |

22 |

11,5 |

50 |

Download data sheet

|

|

|

Standard welding electrode caps ISO 5821 |

13-20 mm |

18-22 mm |

CuCr1Zr Powerode Cr+ |

|

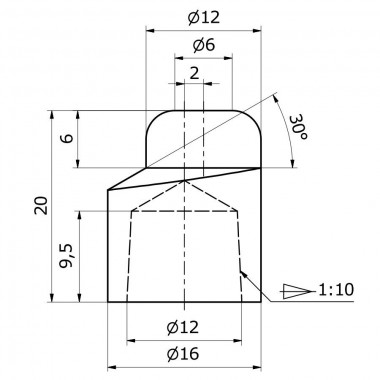

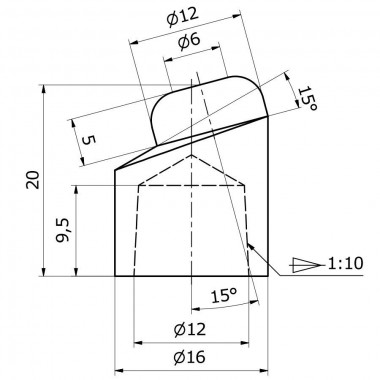

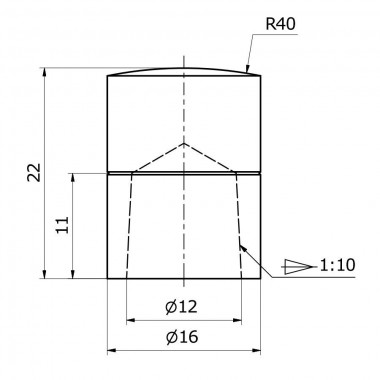

Form C

Welding electrode caps ISO 5821/DIN 44750

Material:

CuCr1Zr Powerode Cr+

Powerode+® - material of very high quality and very high purity. The technology of the production process allows for an increase in service life up to 20% and provides better electrical conductivity compared to standard electrodes.

Pressure forces:

2,5 - 6,3 [kN]

| d1 h11 |

d3 |

L1 |

L2 +0,5 |

| 13 |

10 |

18 |

8 |

| 16 |

12 |

20 |

10,5 |

| 20 |

15 |

22 |

11,5 |

Download data sheet

|

|

|

Standard welding electrode caps ISO 5821 |

13-20 mm |

18-22 mm |

CuCr1Zr Powerode Cr+ |

|

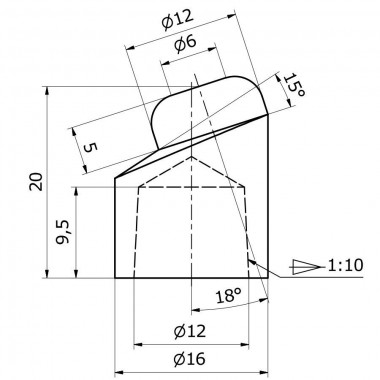

Form D

Welding electrode caps ISO 5821/DIN 44750

Material:

CuCr1Zr Powerode Cr+

Powerode+® - material of very high quality and very high purity. The technology of the production process allows for an increase in service life up to 20% and provides better electrical conductivity compared to standard electrodes.

Pressure forces:

2,5 - 6,3 [kN]

| d1 h11 |

d2 |

d3 |

L1 |

L2 +0,5 |

e |

R1 |

| 13 |

5 |

10 |

18 |

8 |

3 |

32 |

| 16 |

6 |

12 |

20 |

10,5 |

4 |

40 |

| 20 |

8 |

15 |

22 |

11,5 |

5 |

50 |

Download data sheet

|

|

|

Standard welding electrode caps ISO 5821 |

13-20 mm |

18-22 mm |

CuCr1Zr Powerode Cr+ |

|

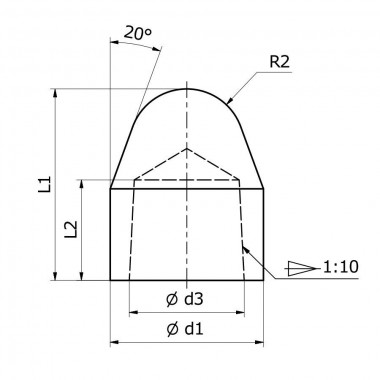

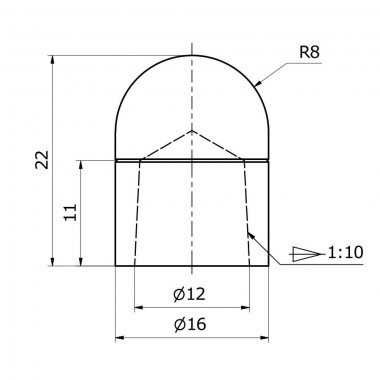

Form E

Welding electrode caps ISO 5821/DIN 44750

Material:

CuCr1Zr Powerode Cr+

Powerode+® - material of very high quality and very high purity. The technology of the production process allows for an increase in service life up to 20% and provides better electrical conductivity compared to standard electrodes.

Pressure forces:

2,5 - 6,3 [kN]

| d1 h11 |

d3 |

L1 |

L2 +0,5 |

R2 |

| 13 |

10 |

18 |

8 |

5 |

| 16 |

12 |

20 |

10,5 |

6 |

| 20 |

15 |

22 |

11,5 |

8 |

Download data sheet

|

|

|

Standard welding electrode caps ISO 5821 |

13-20 mm |

18-22 mm |

CuCr1Zr Powerode Cr+ |

|

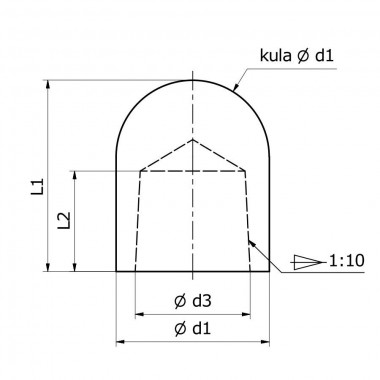

Form F

Welding electrode caps ISO 5821/DIN 44750

Material:

CuCr1Zr Powerode Cr+

Powerode+® - material of very high quality and very high purity. The technology of the production process allows for an increase in service life up to 20% and provides better electrical conductivity compared to standard electrodes.

Pressure forces:

2,5 - 6,3 [kN]

| d1 h11 |

d3 |

L1 |

L2 +0,5 |

| 13 |

10 |

18 |

8 |

| 16 |

12 |

20 |

10,5 |

| 20 |

15 |

22 |

11,5 |

Download data sheet

|

|

|

Standard welding electrode caps ISO 5821 |

13-20 mm |

18-22 mm |

CuCr1Zr Powerode Cr+ |

|

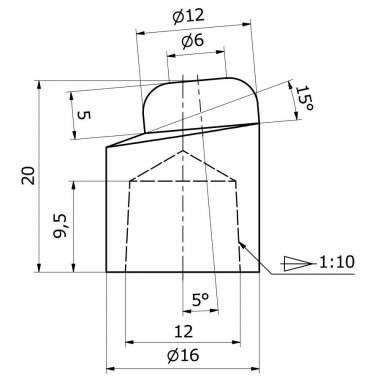

Form G

Welding electrode caps ISO 5821/DIN 44750

Material:

CuCr1Zr Powerode Cr+

Powerode+® - material of very high quality and very high purity. The technology of the production process allows for an increase in service life up to 20% and provides better electrical conductivity compared to standard electrodes.

Pressure forces:

2,5 - 6,3 [kN]

| d1 h11 |

d2 |

d3 |

L1 |

L2 +0,5 |

R1 |

R2 |

α |

| 13 |

5 |

10 |

18 |

8 |

32 |

5 |

- |

| 16 |

6 |

12 |

20 |

10,5 |

40 |

6 |

15° |

| 20 |

8 |

15 |

22 |

11,5 |

50 |

8 |

22,5° |

Download data sheet

|

|

|

Spot welding electrode caps according to automotive manufacturers standards |

16 mm |

20 mm |

CuCr1Zr Powerode Cr+ |

|

3.9.1

Spot welding electrode caps - automotive manufacturer standards

Material:

CuCr1Zr Powerode Cr+

Powerode+® - material of very high quality and very high purity. The technology of the production process allows for an increase in service life up to 20% and provides better electrical conductivity compared to standard electrodes.

Download data sheet

|

|

|

Spot welding electrode caps according to automotive manufacturers standards |

16 mm |

20 mm |

CuCr1Zr Powerode Cr+ |

|

3.9.2

Spot welding electrode caps - automotive manufacturer standards

Material:

CuCr1Zr Powerode Cr+

Powerode+® - material of very high quality and very high purity. The technology of the production process allows for an increase in service life up to 20% and provides better electrical conductivity compared to standard electrodes.

Download data sheet

|

|

|

Spot welding electrode caps according to automotive manufacturers standards |

16 mm |

20 mm |

CuCr1Zr Powerode Cr+ |

|

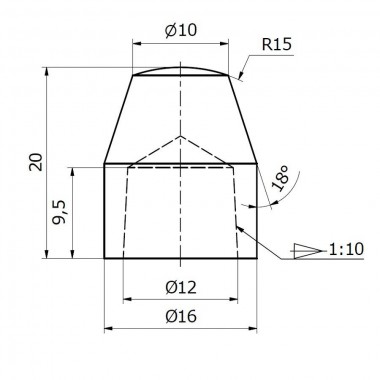

3.9.3

Spot welding electrode caps - automotive manufacturer standards

Material:

CuCr1Zr Powerode Cr+

Powerode+® - material of very high quality and very high purity. The technology of the production process allows for an increase in service life up to 20% and provides better electrical conductivity compared to standard electrodes.

Download data sheet

|

|

|

Spot welding electrode caps according to automotive manufacturers standards |

16 mm |

20 mm |

CuCr1Zr Powerode Cr+ |

|

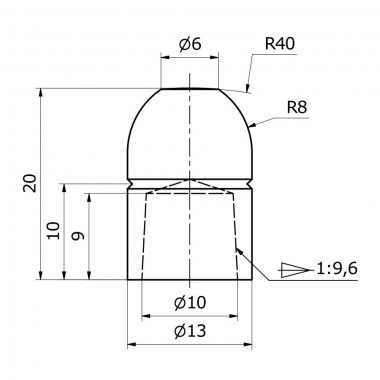

3.9.4

Spot welding electrode caps - automotive manufacturer standards

Material:

CuCr1Zr Powerode Cr+

Powerode+® - material of very high quality and very high purity. The technology of the production process allows for an increase in service life up to 20% and provides better electrical conductivity compared to standard electrodes.

Download data sheet

|

|

|

Spot welding electrode caps according to automotive manufacturers standards |

16 mm |

20 mm |

CuCr1Zr Powerode Cr+ |

|

3.9.5

Spot welding electrode caps - automotive manufacturer standards

Material:

CuCr1Zr Powerode Cr+

Powerode+® - material of very high quality and very high purity. The technology of the production process allows for an increase in service life up to 20% and provides better electrical conductivity compared to standard electrodes.

Download data sheet

|

|

|

Spot welding electrode caps according to automotive manufacturers standards |

16 mm |

20 mm |

CuCr1Zr Powerode Cr+ |

|

3.9.6

Spot welding electrode caps - automotive manufacturer standards

Material:

CuCr1Zr Powerode Cr+

Powerode+® - material of very high quality and very high purity. The technology of the production process allows for an increase in service life up to 20% and provides better electrical conductivity compared to standard electrodes.

Download data sheet

|

|

|

Spot welding electrode caps according to automotive manufacturers standards |

16 mm |

22 mm |

CuCr1Zr Powerode Cr+ |

|

39D 1978/1

Spot welding electrode caps - automotive manufacturer standards

Material:

CuCr1Zr Powerode Cr+

Powerode+® - material of very high quality and very high purity. The technology of the production process allows for an increase in service life up to 20% and provides better electrical conductivity compared to standard electrodes.

Download data sheet

|

|

|

Spot welding electrode caps according to automotive manufacturers standards |

16 mm |

22 mm |

CuCr1Zr Powerode Cr+ |

|

39D 1978/2

Spotwelding electrode caps - automotive manufacturer standards

Material:

CuCr1Zr Powerode Cr+

Powerode+® - material of very high quality and very high purity. The technology of the production process allows for an increase in service life up to 20% and provides better electrical conductivity compared to standard electrodes.

Download data sheet

|

|

|

Spot welding electrode caps according to automotive manufacturers standards |

16 mm |

22 mm |

CuCr1Zr Powerode Cr+ |

|

39D 1978/3

Spot welding electrode caps - automotive manufacturer standards

Material:

CuCr1Zr Powerode Cr+

Powerode+® - material of very high quality and very high purity. The technology of the production process allows for an increase in service life up to 20% and provides better electrical conductivity compared to standard electrodes.

Download data sheet

|

|

|

Spot welding electrode caps according to automotive manufacturers standards |

16 mm |

22 mm |

CuCr1Zr Powerode Cr+ |

|

39D 1978/4

Spot welding electrode caps - automotive manufacturer standards

Material:

CuCr1Zr Powerode Cr+

Powerode+® - material of very high quality and very high purity. The technology of the production process allows for an increase in service life up to 20% and provides better electrical conductivity compared to standard electrodes.

Download data sheet

|

|

|

Spot welding electrode caps according to automotive manufacturers standards |

16 mm |

20 mm |

CuCr1Zr Powerode Cr+ |

|

58V 3210 P

Spot welding electrode caps - automotive manufacturer standards

Material:

CuCr1Zr Powerode Cr+

Powerode+® - material of very high quality and very high purity. The technology of the production process allows for an increase in service life up to 20% and provides better electrical conductivity compared to standard electrodes.

Download data sheet

|

WCTR 13x6A (W-CT-R-13x6A)

|

Spot welding electrode caps according to automotive manufacturers standards |

13 mm |

20 mm |

CuCr1Zr Powerode Cr+ |

|

WCTR 13x6A (W-CT-R-13x6A)

Spot welding electrode caps - automotive manufacturer standards

Material:

CuCr1Zr Powerode Cr+

Powerode+® - material of very high quality and very high purity. The technology of the production process allows for an increase in service life up to 20% and provides better electrical conductivity compared to standard electrodes.

Download data sheet

|

WCTR 16x6A (W-CT-R-16x6A)

|

Spot welding electrode caps according to automotive manufacturers standards |

16 mm |

23 mm |

CuCr1Zr Powerode Cr+ |

|

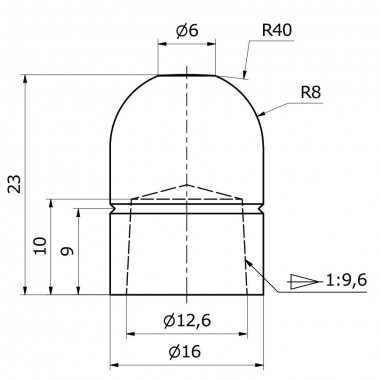

WCTR 16x6A (W-CT-R-16x6A)

Spot welding electrode caps - automotive manufacturer standards

Material:

CuCr1Zr Powerode Cr+

Powerode+® - material of very high quality and very high purity. The technology of the production process allows for an increase in service life up to 20% and provides better electrical conductivity compared to standard electrodes.

Download data sheet

|

|

|

Male electrode caps |

16 mm |

21 mm |

CuCr1Zr Powerode Cr+ |

|

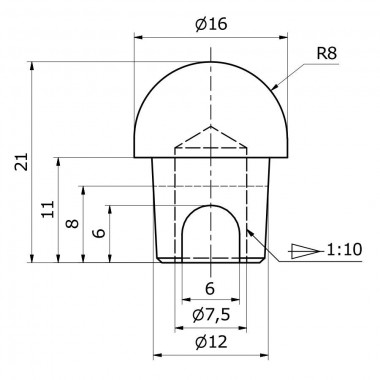

11-59D 311 619/A

Male electrode cap - automotive manufacturer standards

Material:

CuCr1Zr Powerode Cr+

Powerode+® - material of very high quality and very high purity. The technology of the production process allows for an increase in service life up to 20% and provides better electrical conductivity compared to standard electrodes.

Download data sheet

|

|

|

Male electrode caps |

16 mm |

21 mm |

CuCr1Zr Powerode Cr+ |

|

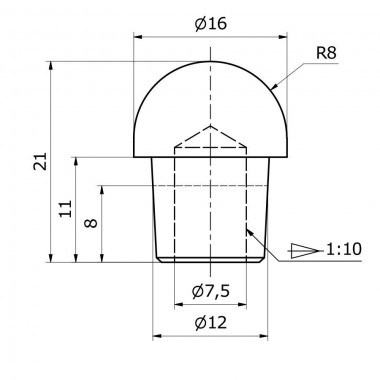

11-59D 311 619/B

Male electrode cap - automotive manufacturer standards

Material:

CuCr1Zr Powerode Cr+

Powerode+® - material of very high quality and very high purity. The technology of the production process allows for an increase in service life up to 20% and provides better electrical conductivity compared to standard electrodes.

Download data sheet

|

|

|

Male electrode caps |

16 mm |

25 mm |

CuCr1Zr Powerode Cr+ |

|

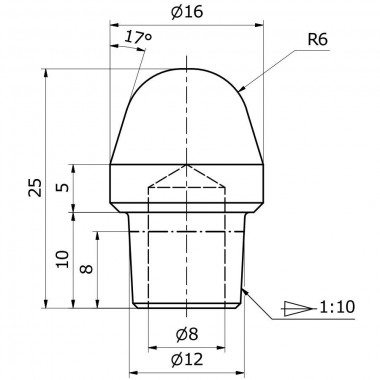

73590

Male electrode cap - automotive manufacturer standards

Material:

CuCr1Zr Powerode Cr+

Powerode+® - material of very high quality and very high purity. The technology of the production process allows for an increase in service life up to 20% and provides better electrical conductivity compared to standard electrodes.

Download data sheet

|

|

|

Swivel electrodes |

22-30 mm |

34-52 mm |

CuCr1Zr |

|

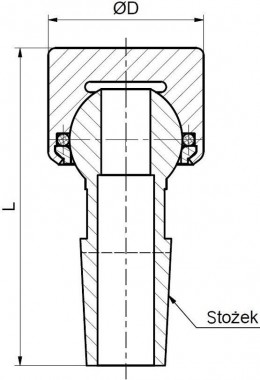

EWL

The swivel electrode is used for non-trace welding of visible points.

The working part of the electrode automatically adjusts its position to the welded material. Thanks to the innovative, direct cooling of the welding part of the electrode, its high durability is achieved.

Additionally, EWAL type electrodes enable the welding of stainless steel in a protective argon atmosphere, which minimizes discoloration.

Material:

CuCr1Zr - recommended for welding carbon and galvanized steel. It is characterized by a very good electrical conductivity with a hardness of approx. 160HB and a high softening point. The most versatile alloy used in resistance welding processes.

| Cone |

ØD |

L |

Symbol |

| Ø12 1:10 |

22 |

42 |

EWL-12-22 |

| Ø12 1:10 |

30 |

45 |

EWL-12-30 |

| Ø15,5 1:10 |

30 |

52 |

EWL-15,5-30 |

| Ø18 1:10 |

30 |

52 |

EWL-18-30 |

| MK1 |

22 |

34 |

EWL-MK1-22 |

| MK2 |

30 |

45 |

EWL-MK2-30 |

Download data sheet

|

|

|

Swivel electrodes |

22-30 mm |

42-56 mm |

CuCr1Zr |

|

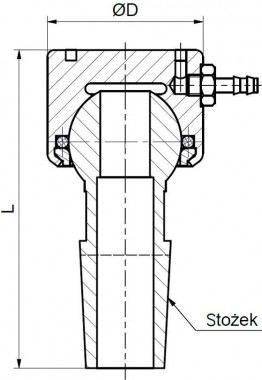

EWAL

The swivel electrode is used for non-trace welding of visible points.

The working part of the electrode automatically adjusts its position to the welded material. Thanks to the innovative, direct cooling of the welding part of the electrode, its high durability is achieved.

Additionally, the EWAL electrode enables the welding of stainless steels in a protective argon atmosphere, which minimizes discoloration.

Material:

CuCr1Zr - recommended for welding carbon and galvanized steel. It is characterized by a very good electrical conductivity with a hardness of approx. 160HB and a high softening point. The most versatile alloy used in resistance welding processes.

|

Cone

|

ØD

|

L

|

Symbol

|

|

Ø12 1:10

|

22

|

42

|

EWAL-12-22

|

|

Ø12 1:10

|

30

|

45

|

EWAL-12-30

|

|

Ø15,5 1:10

|

30

|

52

|

EWAL-15,5-30

|

|

Ø18 1:10

|

30

|

52

|

EWAL-18-30

|

|

MK1

|

22

|

42

|

EWAL-MK1-22

|

|

MK2

|

30

|

56

|

EWAL-MK2-30

|

Download data sheet

|

|

|

- |

up to 350 mm |

- |

CuCr1Zr, CuCo2Be, CuCoNiBe |

|

Seam welding wheels

The electrode wheels for seam welding produced by us are made according to the customer's documentation.

Our design office helps with documentation problems and in the case of individual customer needs.

Diameter range:

up to Ø 350 mm.

Material:

CuCr1Zr - recommended for welding carbon and galvanized steel. It is characterized by a very good electrical conductivity with a hardness of approx. 160HB and a high softening point. The most universal alloy used in resistance welding processes.

CuCo2Be / CuCoNiBe - A material with very good mechanical parameters and hardness combined with lower electrical conductivity than alloys with zircon and chromium. Recommended for seam welding, among others stainless steels.

|

|

|

- |

- |

- |

CuCr1Zr, CuNi2SiCr, CuCo2Be (CuCoBe, CuCoNiBe), CuNi2Be, WCu, W, NiCu30Fe, Mo |

|

Special electrodes

Our customers define shape and material specification of this type of electrodes. Our main clients are automobile manufacturer, producers of household appliances, central heating radiators, grilles and fences. A large part of this type of products is exported.

We provide comprehensive technical service along with the creation of executive documentation based on the submitted patterns. We attach quality control cards to all products, and we present material certificates on request.

The group of these products includes electrodes of various shapes for welding: sheets, bars, tubes, meshes and others.

|

|

|

- |

12-22 mm |

- |

Vanadium-Extra and CuCrZr |

|

Electrode wrenches

We offer the highest quality wrenches for easy and safe disassembly of electrodes tips. The customer can choose the version without a hammer or with a hammer. The second version allows you to install the electrode without damaging its surface.

Diameter range:

12-22 mm.

Material:

Vanadium-Extra and CuCrZr.

|