|

|

- |

CuCr1Zr, CuNi2SiCr, CuCo2Be, CuCoBe, CuCoNiBe, CuNi2Be, CuBe2, WCu, W, NiCu30Fe, Mo |

|

Material table

The table shows the types of materials available in our offer. More information on material properties can be found in the downloadable catalog below the table.

|

Material

|

Name

|

Norms

|

Chemical composition %

|

Hardness HB

|

Electrical conductivity % IACS

|

Electrical conductivity MS/m

|

Thermal conductivity 20°–200°C

|

Softening point °C

|

Application

|

|

CuCr1Zr

|

CRM16

|

MHY, 2.1293, C18100, CW106C, Class RWMA 2

|

Cr 0,4-1, Zr 0,03-0,15, Fe 0,08, Cu rest

|

120-150

|

>75

|

>44

|

320

|

500

|

Material for electrodes, holders, arms and plates for welding devices. Optimal for welding carbon and galvanized steels. It has a very good electrical conductivity with a hardness of approx. 160HB and a high softening point. The material is suitable for cold bending. The most universal alloy used in resistance welding processes.

|

|

CuNi2SiCr

|

NS6

|

~ 2.0855, C18000, CW111C, Class RWMA 3

|

Ni 2,3, Si 0,6, Cr 0,6, Cu rest

|

160-195

|

>45

|

>26

|

180

|

480

|

Material for electrodes, holders and arms. Its hardness and conductivity make it often used as an alternative to the more robust in terms of mechanical properties alloy with beryllium. This material is often used in applications where beryllium alloys are contraindicated. Often commonly abbreviated as NCS.

|

|

CuCo2Be (CuCoBe, CuCoNiBe)

|

CB4

|

BC2, 2.1285, C17500 , CW104C, Class RWMA 3

|

Co 2,2, Be 0,5, Cu rest

|

220-240

|

>43

|

>25

|

200

|

480

|

Very good mechanical parameters and hardness combined with lower electrical conductivity than alloys with zircon and chrome. Mainly used in projection and butt welding processes. Recommended for spot and seam welding of stainless steels.

|

|

CuNi2Be

|

CNB spec.

|

2.0850, C17510, CW110C, Class RWMA 3

|

Co 0,3, Ni 1,9, Be 0,4, Si 0,2, Fe 0,2, Cu rest

|

220

|

>65

|

>38

|

270-320

|

480

|

Recommended for welding stainless and heat-resistant steels. High hardness and mechanical strength with good thermal and electrical conductivity. Optimal alloy for seam welding of stainless steel.

|

|

CuBe2

|

CBE2

|

BB2, 2.1247, C17200, CW101C, Class RWMA 4

|

Co 0,2, Be 1,8-2, Cu rest

|

320–360

|

28

|

16

|

110

|

300

|

An alloy with the best mechanical properties. Used when the element also transfers extreme mechanical forces. Recommended for injection mold inserts, grips and welding jaws. Virtually not used as a resistance welding material due to its very low electrical conductivity.

|

|

W70Cu

|

WCu 70/30

|

W70, 5182, B702, Class RWMA 10

|

W 70, Cu 30

|

160–220

|

44-52

|

>26

|

200

|

>1000

|

Tungsten sinter used for projection and butt welding electrodes. Welding conductive materials, e.g. copper and brass. Reusable electrodes for die sinking EDM machines and inserts for resistance upsetting and riveting. Recommended for heating teeth for hardening steel. In the case of electrodes, usually only the working insert is used from sinter.

|

|

W75Cu

|

WCu 75/25

|

W75, 5182, B702, Class RWMA 11

|

W 75, Cu 25

|

180-250

|

41-48

|

>24

|

190

|

>1000

|

Tungsten sinter used for projection and butt welding electrodes. Welding conductive materials, e.g. copper and brass. Reusable electrodes for die sinking EDM machines and inserts for resistance upsetting and riveting. Recommended for heating teeth for hardening steel. In the case of electrodes, usually only the working insert is used from sinter.

|

|

W80Cu

|

WCu 80/20

|

W80, 5182, B702, Class RWMA 12

|

W 80, Cu 20

|

200–280

|

38-45

|

>22

|

170

|

>1000

|

Tungsten sinter used for projection and butt welding electrodes. Welding conductive materials, e.g. copper and brass. Reusable electrodes for die sinking EDM machines and inserts for resistance upsetting and riveting. Recommended for heating teeth for hardening steel. In the case of electrodes, usually only the working insert is used from sinter.

|

|

W (99,95%)

|

Tungsten

|

W, 6848, B777, Class RWMA 13

|

W 99,95

|

320–370

|

>31

|

>18

|

125

|

>1000

|

It is used for welding conductive materials, e.g. copper and brass. Due to the price, usually only the working insert is made of tungsten, the electrode is made of CuCr1Zr material.

|

|

NiCu30Fe

|

Monel

|

2.4360, B164, Class RWMA 14

|

Cu 28-34, Fe 2,5, C 0,3, Mn 2, Si 0,05, S 0,024 Ni rest

|

150-210

|

>52

|

>30

|

22

|

1300

|

Nickel-copper alloy with high strength and resistance to sea water, acids and alkalis. It maintains very good mechanical properties at low temperatures, it is also adapted to high temperatures, reaching 537 ⁰C. Used for the production of electrode supports and electrode holder sleeves.

|

|

Mo (99,99%)

|

Molybdenum

|

Mo, B387, Class RWMA 13

|

Mo 99,99

|

190-220

|

>35

|

>20

|

130

|

870

|

Due to properties, it is more resistant to mechanical and thermal shock than tungsten. Used for welding conductive materials, e.g. copper and brass. Also used for the production of heating electrodes. Due to the price, usually only a molybdenum working insert is used, the electrode is made of CuCr1Zr.

|

Download catalog

Hovadur CCZ Hovadur CNCS Hovadur CANF Hovadur CAF Hovadur CCNB Hovadur CCNB-EH Hovadur CNB-Special Hovadur CB2 CuCr1Zr CuNi2SiCr CuAl10Ni CuAl10 CuCoNiBe CuCoNiBe CuNi2Be CuBe2 DIN 2.1293 2.0855 2.0966 2.1285 2.1285 2.0850 2.1247 CW106C CW112C CW307G CW103C CW103C CW110C CW101C TZM Allper 82 Allper 45 Allper 52 Allper 50 Allper 22H Mallory 328 Mallory 100 Elbrodur N Elbrodur D Elbrodur B Elbrodur GHF Elbrodur RS CRM 16 NS 5 NC 4 CB 4 CBE 2 Vakudur CCZ Vakudur CNCS Vakudur CCNB Vakudur B20 Eldur II Eldur III Eldur IV Elmedur X Elmedur NCS Elmedur HA Elmedur B2 Protherm Moldmax Wirbalit HF Wirbalit N Wirbalit G Wirbalit D Wirbalit B AMPCO 120 972 AMPCO 940 AMPCO 91 AMPCO 95 AMPCO 83 Ampco 88 Ampcoloy Soudalox 100 soudalox 200 soudalox 300 M1E

|

|

|

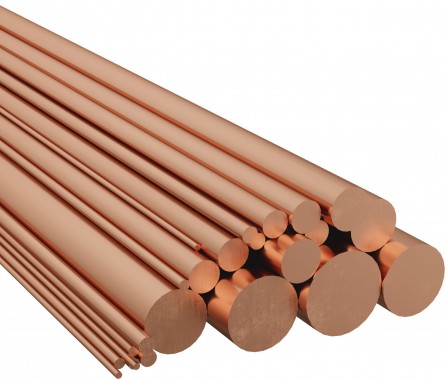

6-209 mm |

CuCr1Zr, CuNi2SiCr, CuCo2Be, CuCoBe, CuCoNiBe, CuNi2Be, CuBe2, WCu, W, NiCu30Fe, Mo |

|

Round bars

Our offer includes round bars made of various grades of copper alloys, but also other materials used in the welding process and more.

At the customer's request, we cut the material according to the submitted quantitative and dimensional specifications, enabling the purchase of any quantity.

Materials:

CuCr1Zr, CuCo2Be (CuCoBe, CuCoNiBe), CuNi2SiCr, CuNi2Be, CuBe2,

And

Tungsten, W70Cu, W75Cu, W80Cu, Monel, Molybdenum.

More information on the availability of materials and their conversion rates can be found in the download data sheet.

Download data sheet

|

|

|

10x10 - 100x100 |

CuCr1Zr, CuNi2SiCr, CuCo2Be, CuCoBe, CuCoNiBe, CuNi2Be, CuBe2, WCu, W |

|

Flat and square bars

Our offer includes rectangular bars (flat and square bars) made of various grades of copper alloys, but also other materials used in the welding process and more.

At the customer's request, we cut the material according to the submitted quantitative and dimensional specifications, enabling the purchase of any quantity.

Materials:

CuCr1Zr, CuCo2Be (CuCoBe, CuCoNiBe), CuNi2SiCr, CuNi2Be, CuBe2,

And

Tungsten, W70Cu, W75Cu, W80Cu.

More information on the availability of materials and their conversion rates can be found in the download data sheet.

Download data sheet

|

|

|

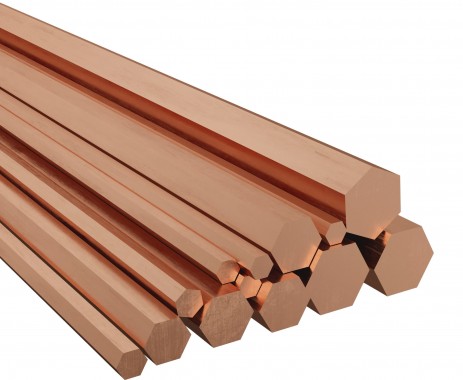

12-36 mm |

CuCr1Zr, CuNi2SiCr, CuCo2Be, CuCoBe, CuCoNiBe |

|

Hexagonal bars

Our offer includes hexagonal bars made of various types of copper alloys used in the welding process and more.

At the customer's request, we cut the material according to the submitted quantitative and dimensional specifications, enabling the purchase of any quantity.

Materials:

CuCr1Zr, CuCo2Be (CuCoBe, CuCoNiBe), CuNi2SiCr.

More information on the availability of materials and their conversion rates can be found in the download data sheet.

Download data sheet

|

|

|

10-100 mm |

CuCr1Zr, CuCo2Be, CuCoBe, CuCoNiBe |

|

Plates

Our offer also includes plates of various types of copper alloys.

At the customer's request, we cut the material according to the quantity and dimensional specification sent, enabling the purchase of any quantity.

The delivery time depends on the dimensions and quantity of the ordered material and is from one to two weeks.

Materials:

CuCr1Zr lub CuCo2Be (CuCoBe, CuCoNiBe).

More information on the availability of materials and their conversion rates can be found in the download data sheet.

Download data sheet

|

|

|

- |

CuCr1Zr, CuCoNiBe |

|

Profiles

We also offer special pressed, aged and drawn profiles.

Materials:

CuCr1Zr lub CuCoNiBe.

More information on the availability of materials and their conversion rates can be found in the download data sheet.

Download data sheet

|

|

|

4x0,5 - 10x1 mm |

M1E |

|

Copper pipes

Copper pipes are important parts of the cooling systems for electrode-holders and arms. Available from our warehouse in Tychy.

Material:

Miedź: M1E z4.

More information on the availability of materials and their conversion rates can be found in the download data sheet.

Download data sheet

|