|

|

|

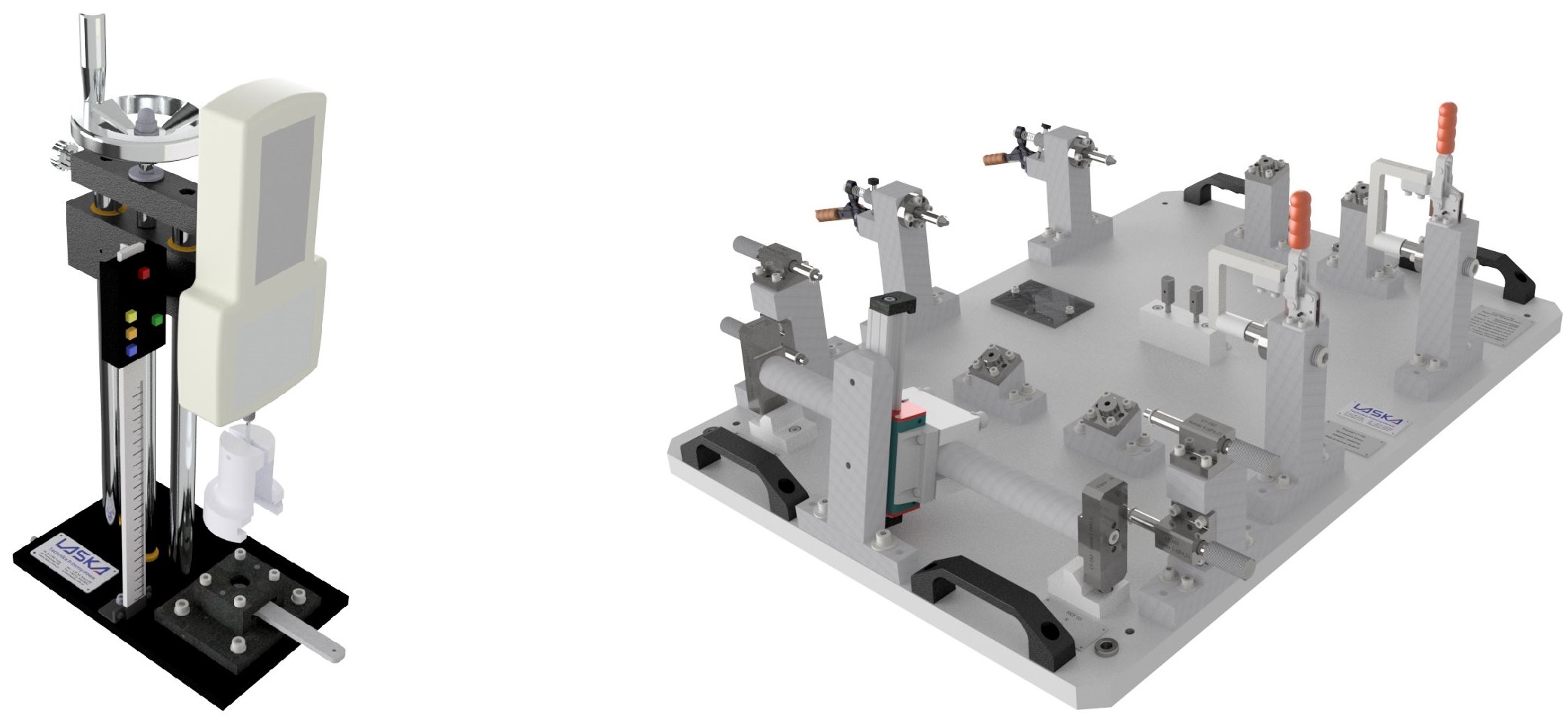

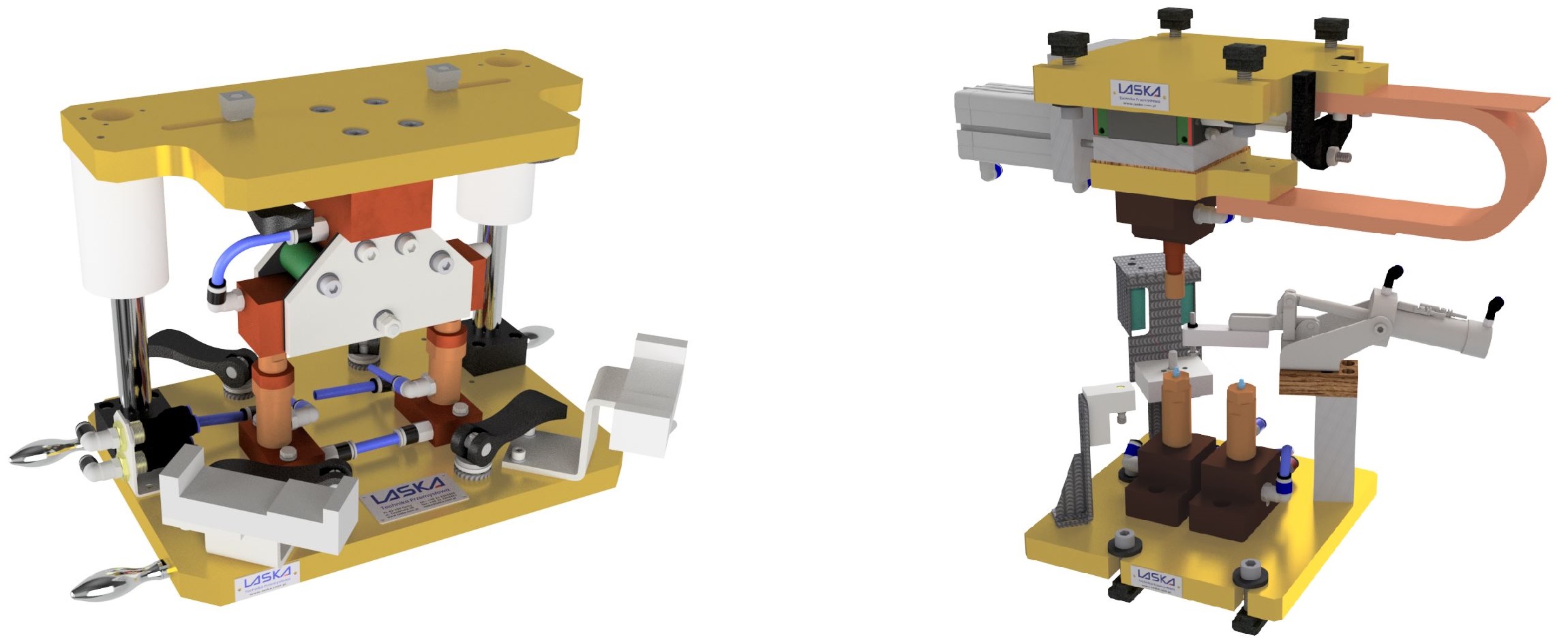

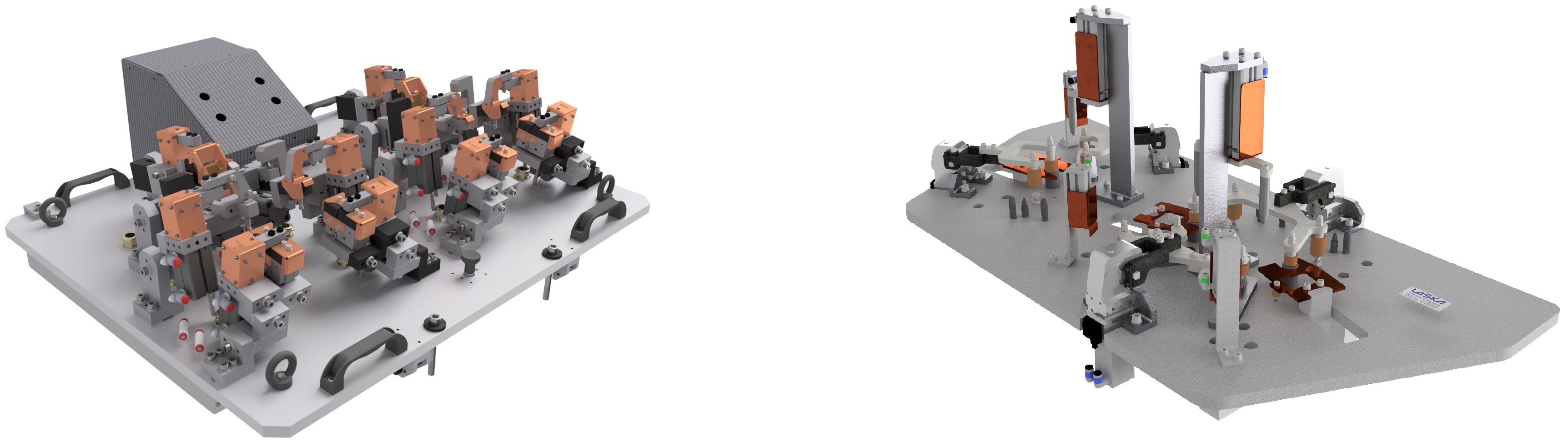

For arc welding

Adapted tools for robotic welding

We make fixtures with a set of sensors, cables and pneumatic clamps and communication with the PLC controller and the welding robot.

As a standard, the devices are equipped with three-axis adjustable workpiece base. On request, we perform calibration on a measuring machine and provide a measurement protocol.

Thanks to many years of experience in the construction of instruments, we use the best materials and standard parts from renowned companies, such as: Festo, Destaco, Amf, Turck, Balluff.

Steel elements are covered with an anti-spatter coating, and all cables are secured against splashes with special protective hoses. We have developed our own technical solutions to protect devices operating in harsh conditions: chipping, high temperature, etc.

Together with the welding fixtures, the customer receives as standard:

- 3D model in STP / IGS format

- List of spare parts

- 2D assembly drawing

Optional, you can also purchase:

- Complete 2D drawing documentation

- Protocols from the measuring machine

- Other engineering services

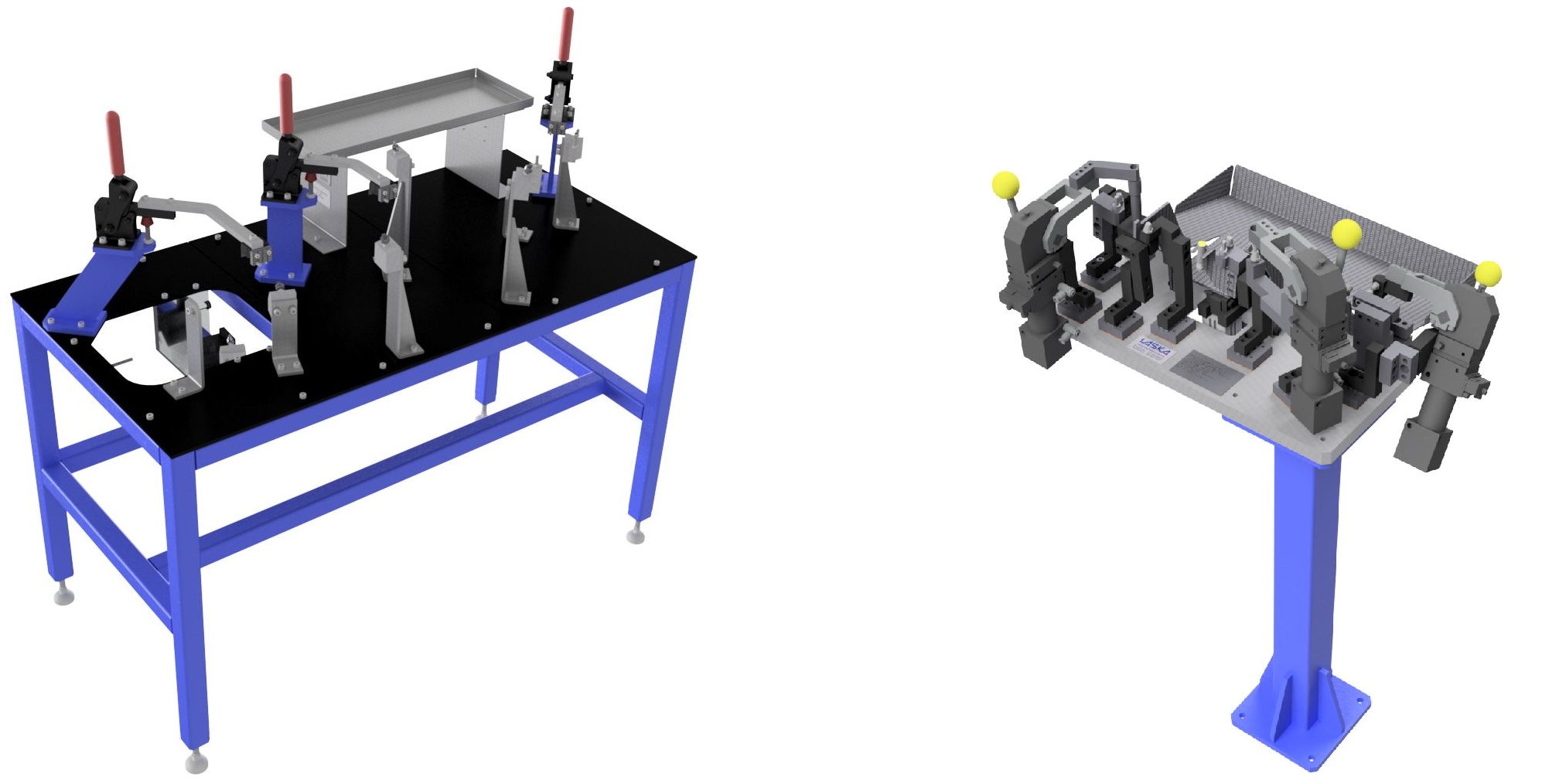

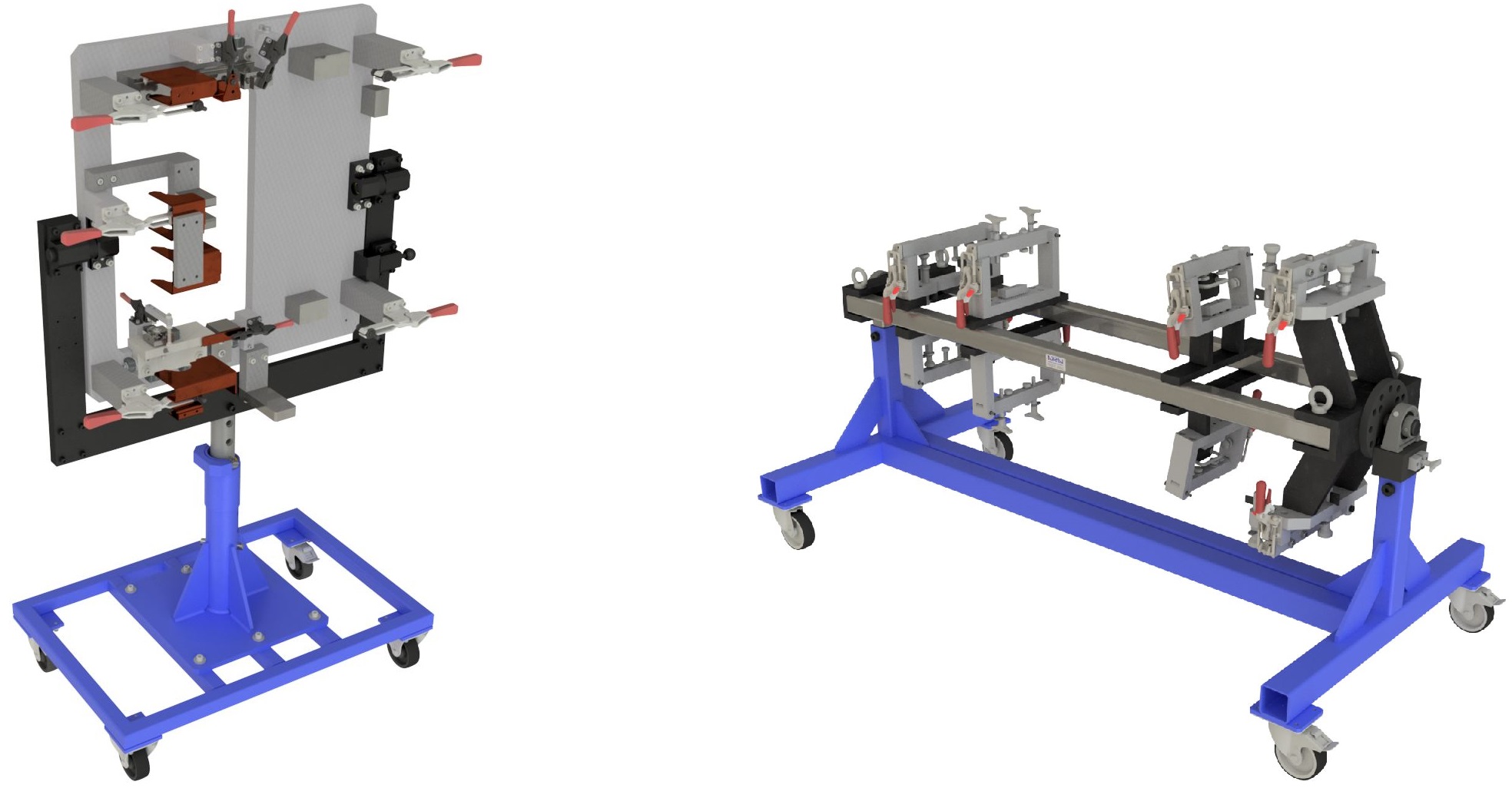

Hand welding fixtures

In these tools are used manual clamps for basing details, mostly: Destaco, Amf or Kipp. The welding fixtures can be attached to a rotarytable. We have our own designs of rotary tables for handheld devices.

|

|

|

|

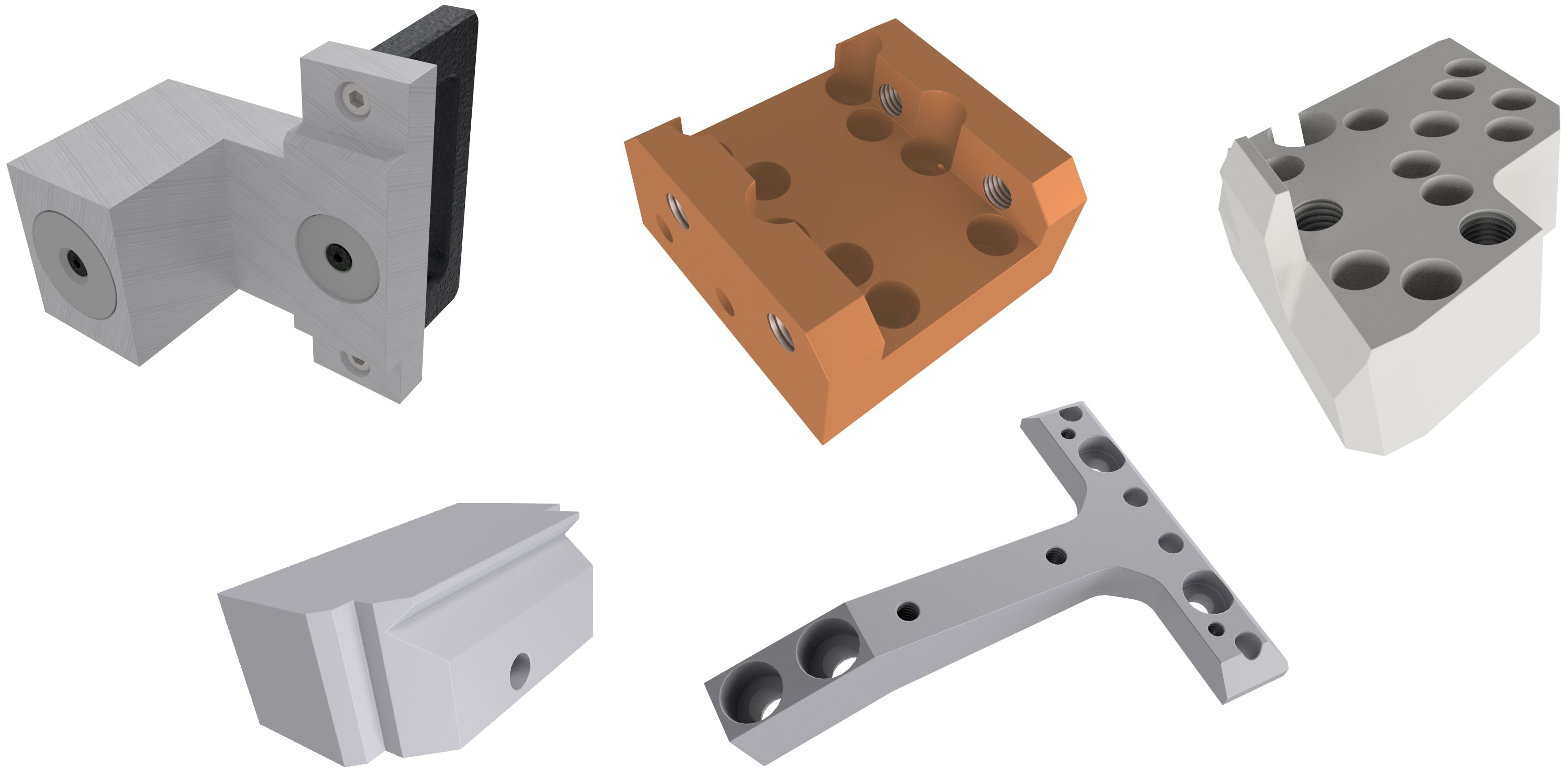

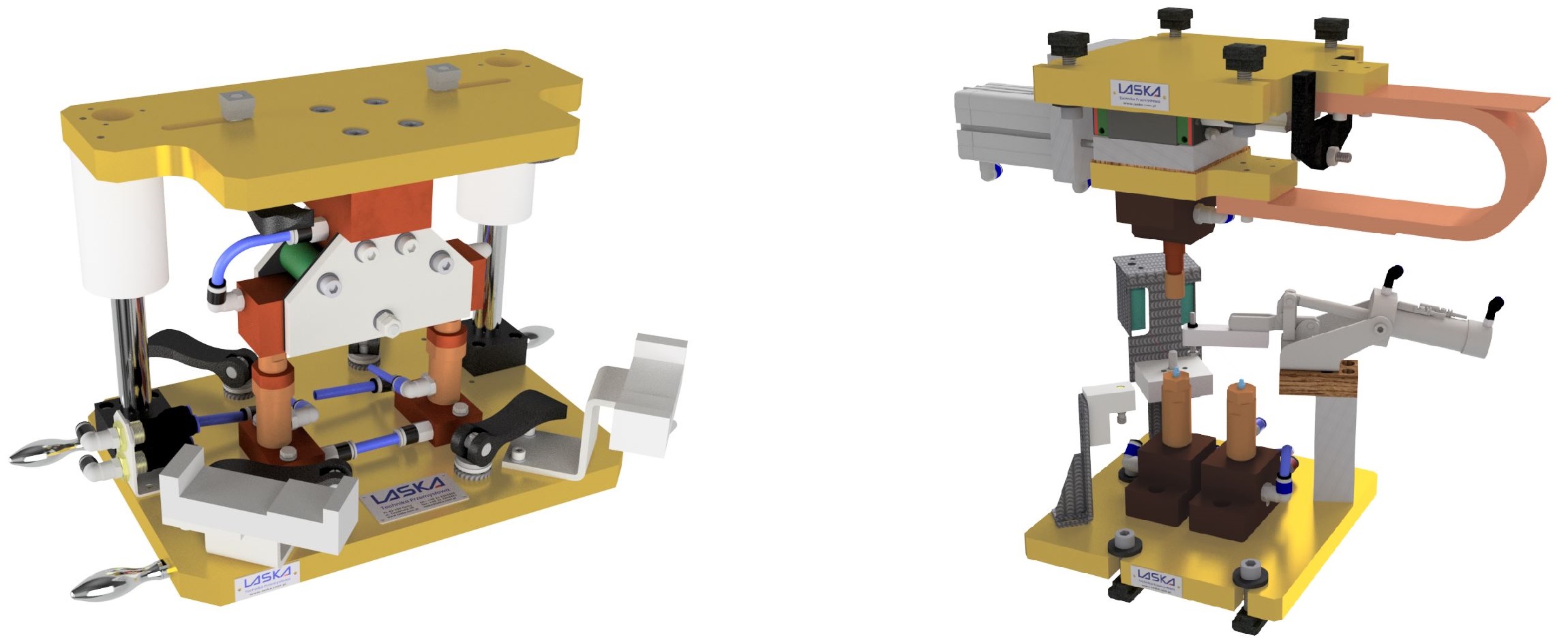

For resistance welding

Projection welding tools for bolts, nuts and studs

We produce projection welding tools with a set of sensors, cables, clamps and the integration of the welding machine PLC controller.

For the production of tools, we use high-quality copper alloys CRM16 and CB4 by Lebronze, which guarantees optimal welding parameters and the best quality of welds. We use the best ceramic insulators and KCF steel (non-conductive). Thanks to that, we eliminate chipping and improve the quality of the connection.

Together with the welding tool, the customer receives as standard:

- 3D model in STP / IGS format

- Spare parts list

- 2D assembly drawing

Optional, you can also purchase:

- Complete 2D drawing documentation

- Other engineering services

Spot welding tools

We make complete spot welding tools for both manual welding and robotic welding. These tools, just like the welding fixtures, are equipped with three-axis adjustable workpiece base. At the customer's request, we prepare a calibration report on a measuring machine.

The spot welding tools can be equipped with manual or pneumatic clamps with sensors, cables and PLC integration.

We have our own design solutions for the suspension of the manual welding gun.

|

|

|

|

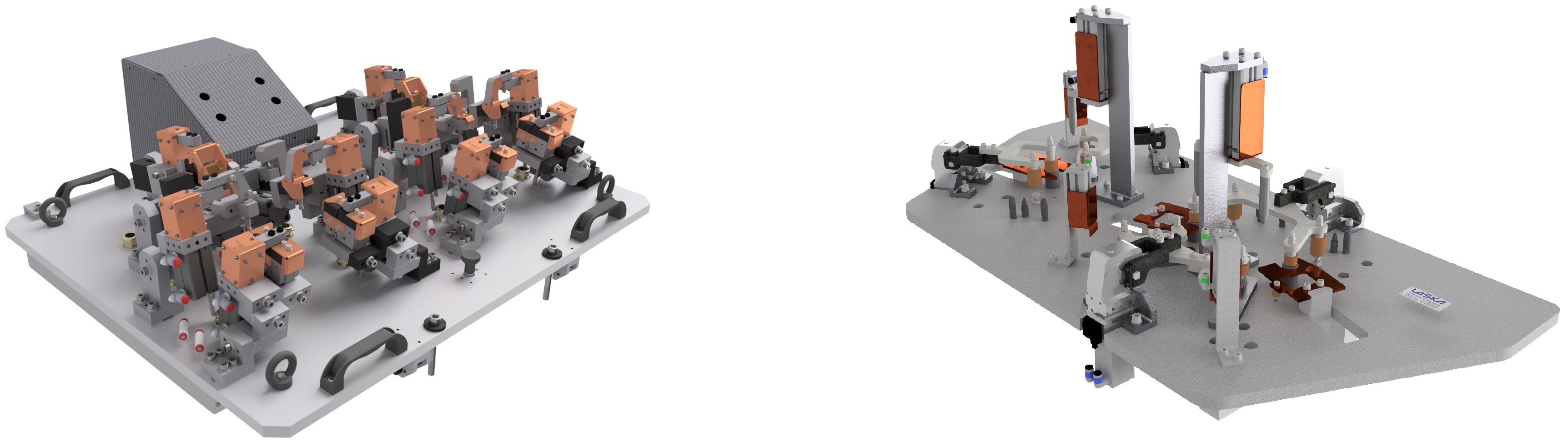

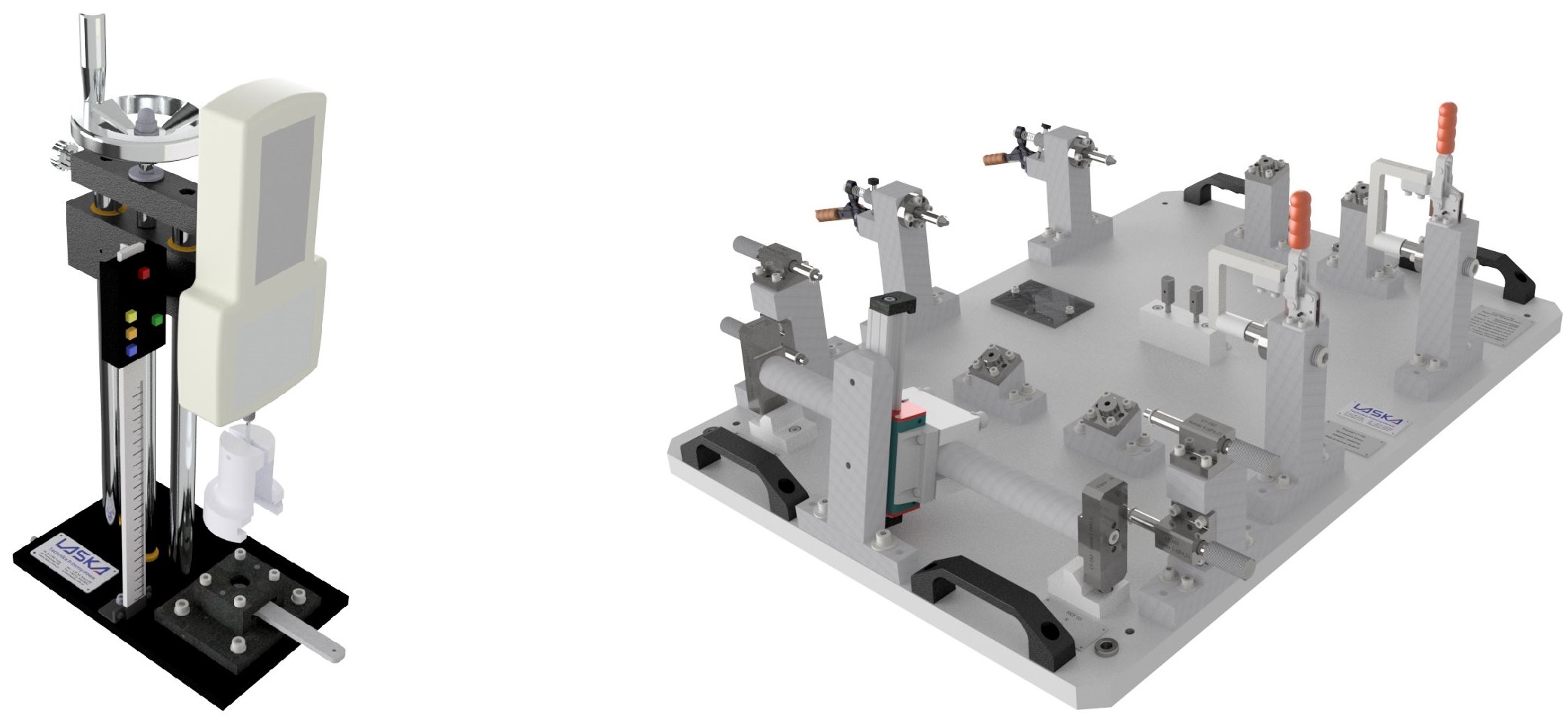

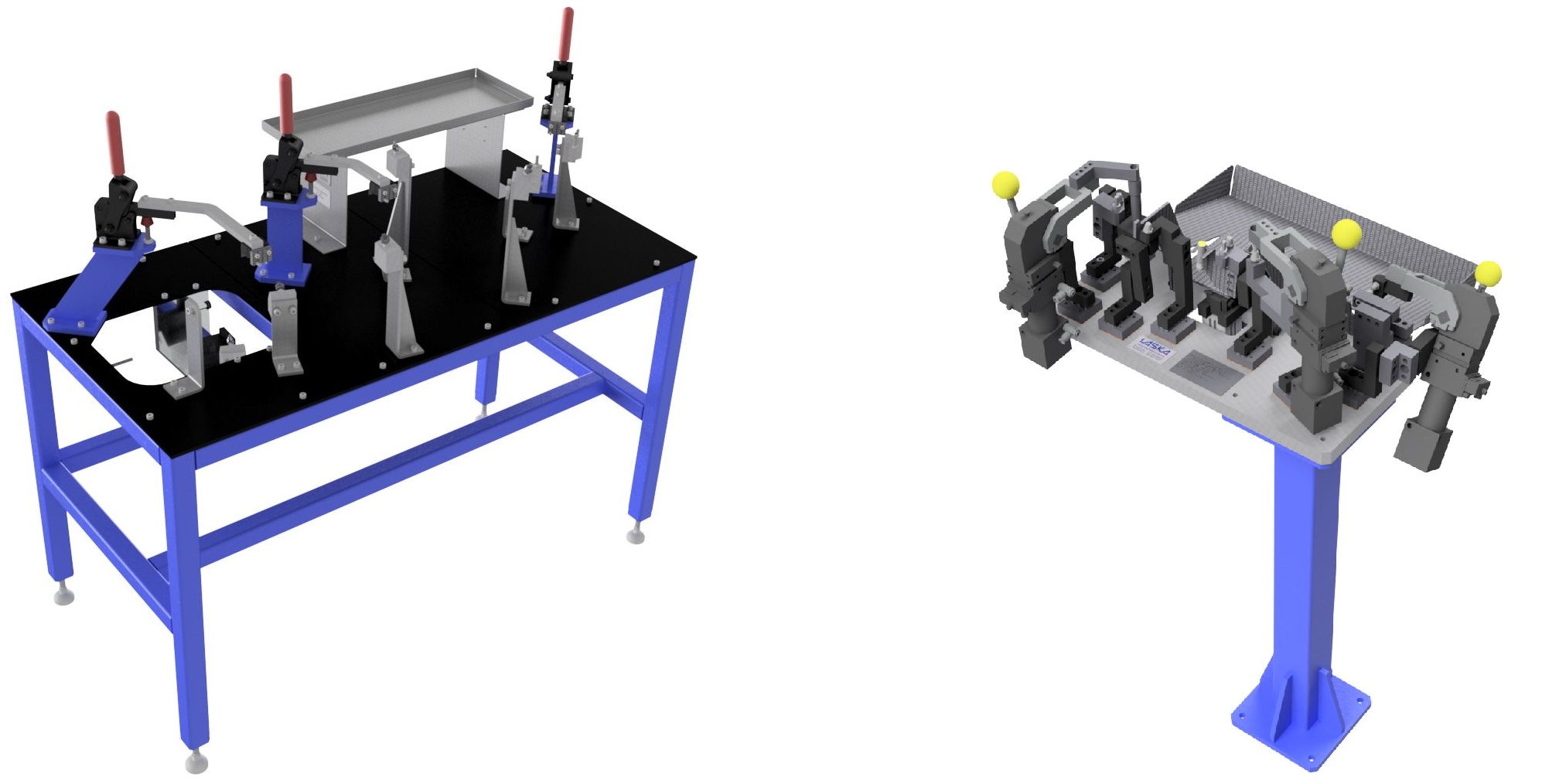

Other tools

Assembly tools

We design and manufacture assembly tools for assembly lines as well as independent sockets for assembling components and assemblies. Jigs can be made as manual or mechanized stations with all the equipment. We make stands based on aluminum profiles or welded steel profiles, powder coated.

We make transport pallets based on the BOSCH Rexroth system, tailored to individual customer requirements.

Complete production stations

_edited_1.jpg)

We build various types of production stations, such as welding booths, assembly tables, and stud welding booths. We build production stands of aluminum profiles of the BOSCH Rexroth type or of steel, welded and powder-coated profiles. The stands are equipped with electric and pneumatic installations. The stations are made in compliance with all ergonomic standards, taking into account the customer's special requirements for special equipment.

Test and control tools

We design and manufacture control and measurement tools, gauges, patterns and other equipment supporting bench and inter-operational control as well as final measurements in a measurement laboratory, including holders for coordinate measuring machines. We offer walk-through / no-go tests.

The test and control tools are calibrated in one of our two laboratories, together with the tools, we provide the customer with a set of measurement documents.

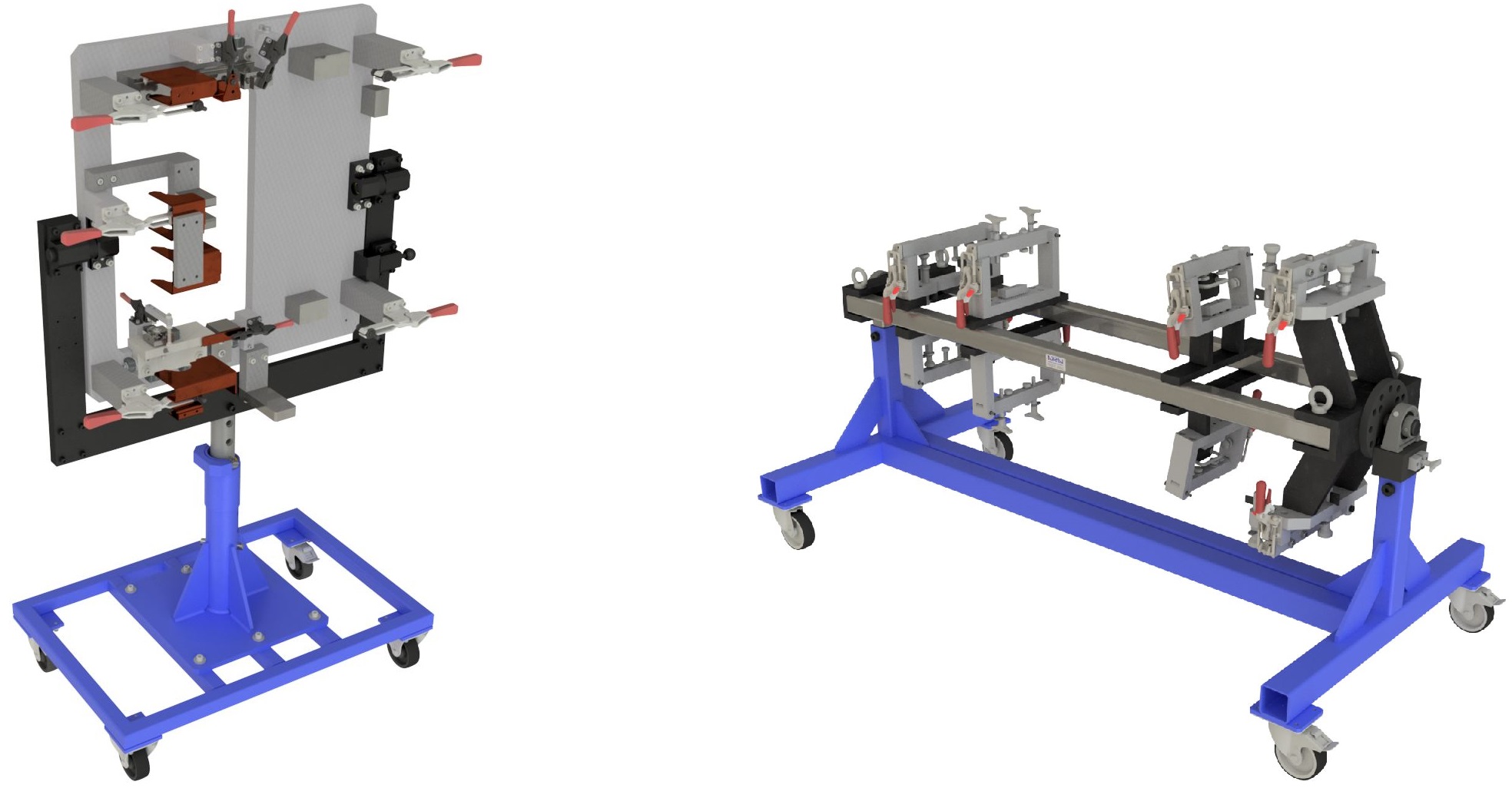

Modification and regeneration of tools

In addition to the design and construction of newwelding tools, we also modify and regenerate existing equipment.

Regeneration consists of an inventory and replacement of all wearing elements such as clamps, sensors, pins and base blocks

|

|

|

|

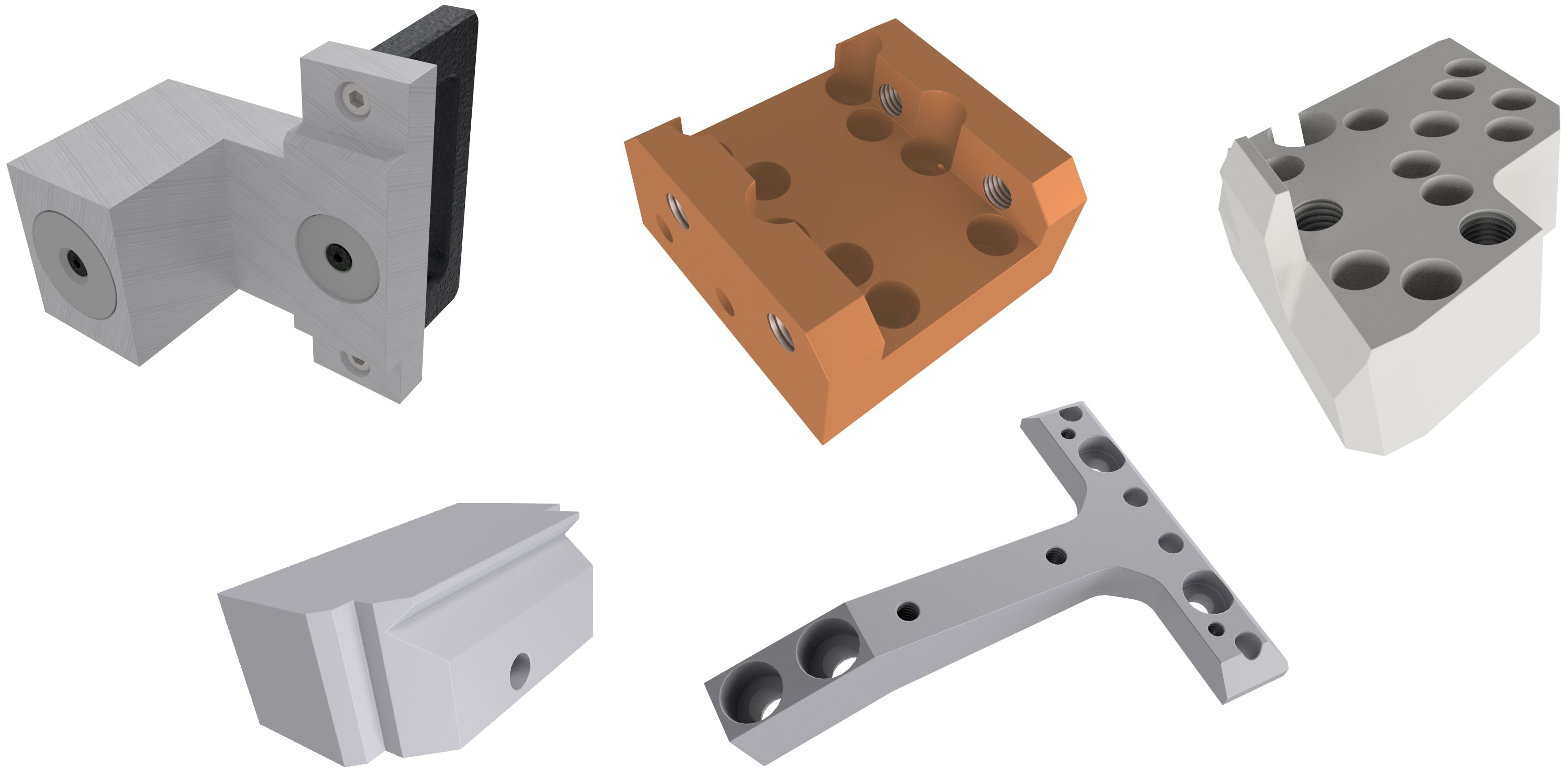

Spare parts for tools

Our engineers undertake the production of wearing parts in working production devices, even in the absence of documentation or when the documentation is out of date.

It is also possible to modify parts of the devices to better fulfill their task or to adapt to technological changes. The experience of our specialists allows for the optimal selection of materials, solutions and adaptation to the production requirements.

|

_edited_1.jpg)